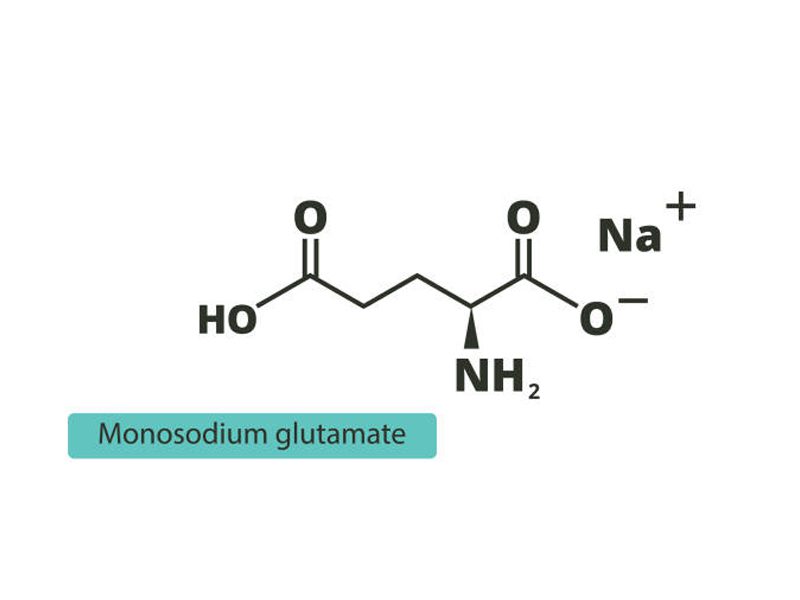

Monosodium Glutamate

PPRB's MSG Quality: We Assure You Safety and Purity

The more glutamic acid content, the purer and better the quality of MSG. On the market, there are different purity marks on the packaging, such as 99%, 90%, 80%, 70%, etc., which refer to the content of glutamic acid in MSG. This is the main factor in catering to the quality of MSG (Glutamic acid in MSG below 70% cannot be labeled as MSG on the packaging), and PRB’s MSG has a purity higher than 99%, which is in line with the top standard in the market.

Flexibility and Personalization in MSG OEM

Pearl River Bridge, ideal MSG Monosodium Glutamate Manufacturer & Supplier. Pearl River Bridge’s OEM services are not limited to soy sauce manufacturing, we also have a wide selection at great prices to help you get creative. All the MSG Flavor Enhancers are quality guaranteed, we are one of the China Origin Factory of Where to Buy Msg. Our commitment to a flexible and comprehensive strategy makes us uniquely suited to be your ideal partner to enable your business to thrive in a diverse and challenging market. If you have any questions, please feel free to contact us.

Monosodium Glutamate MSG Production Process

MSG Application

How MSG Benefit Food Process Manufacturers?

Cost-Effective

Cost-Effective

Improving Texture

Improving Texture

Reliable MSG Supplier Meets International Food Safety Standards

We’ve proudly displayed our distinctive Dark Soy Sauce at global exhibitions. These events show just how much people around the world love our product. From Asian households to Western high-end eateries, and from world-class food festivals to expert kitchens, PRB’s Dark Soy Sauce is renowned and cherished everywhere.

Hi! Click one of our members below to chat on