Selection

PRB practices a strict selection process for our soybeans – size, body, physical, and chemical factors must meet our requirements. Never stopping our search for the best soybeans, we source raw materials from renowned locations and brought to our factory directly.

Steaming

The soybeans are steamed at a closed ultra-high temperature using a fully-automatic continuous steaming system. The process eliminates contamination from human sources and external sources while bringing out the beans’ naturally sweet taste and pleasant fragrance.

Additionally, the proteins in the beans become denatured, making the release of amino acids, peptides, and monosaccharides during fermentation more effective.

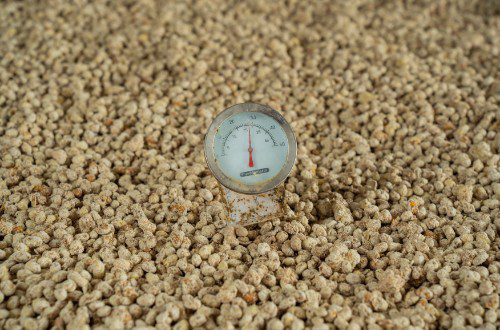

Propagating

The koji mold is added to the steamed soy beans and wheat, which is then moved to a perfectly-conditioned location to facilitate the propagation of the mold. The three-day process leads to the production of the base material for our soy sauce.

Fermentation

After the koji base has formed, it is then moved to a tank and mixed with a solution of salt and water. The mixture is called a mormoi, which can ferment for about 100 days. The process brings out the rich and aromatic character that our soy sauce is known for.

Pressing

Once the aging process is done, the mormoi is pressed through several layers of fabric, with each layer having three sub-layers. The soy sauce is initially allowed to flow naturally and then slowly pressed mechanically for about 10 hours.

The raw soy sauce is then moved to another tank for three to four days, allowing the components to separate and enhance their flavors. The clarified soy sauce is then run through a steam pipe to heat, halting the enzyme activity and stabilizing its flavors.

Bottling

We implement an established quality control process to ensure our soy sauce is bottled correctly. Seasoned quality inspectors ran several tests to verify that the color, flavor, and aroma meets our standards.

Hi! Click one of our members below to chat on